Calculation method of graphite electrode consumption in electric arc furnace

Calculation method of graphite electrode consumption in electric arc furnace

(Summary description)The graphite electrode is the last part of the electric arc furnace power supply short network. Through the end of the graphite electrode, a strong electric arc is generated to melt the furnace charge and heat the molten steel. That is, the electrode is the central hub that converts electric energy into heat energy. The electrode is subjected to high temperature when working, and the furnace gas is oxidized. As well as the effects of collapse and impact, especially the connection between the two electrodes, the resistance is larger and the conductivity is lower than other places, and it is easy to trip, oxidize, fall off, and break, which causes great consumption of electrodes and prolongs the smelting time. Reduced productivity.

In 1982, Bowman divided the normal consumption of electrodes into front-end consumption and lateral consumption. Both can be calculated by the following formula:

Electrode normal consumption: CE=Cγ+Cs

Front-end consumption: Cγ=Vγ·TOntap/W, Vγ=Kγ·I2/dnγ

In the formula: TOntap————Electric furnace power supply time, h;

W———Electric furnace tapping weight, t;

Vγ———the front end consumption speed of the electrode, kg/h;

Kγ-front-end consumption constant (Bowman gives Kγ=0.0361 and n usually 0.58 for AC arc furnace);

I-arc current intensity, kA;

dγ—The diameter of the front end of the electrode, m.

Side consumption: Cs=Vs·TTop-Top/W, Vs=3Ks·S

In the formula: TTop-Top --- electric furnace smelting cycle, h;

W———Electric furnace tapping weight, t;

Vs———The consumption speed of the electrode side, kg/h;

Ks———oxidation consumption rate, kg/(m2·h);

S————The oxidation surface area in the electrode furnace, m2.

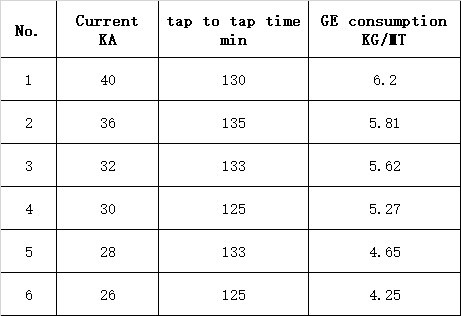

At present, in the production process, the Bowman electrode consumption model has been widely recognized. Wang Mingli and others believe that once the smelting process is stable, the power supply current has the greatest impact on the electrode unit consumption, and according to the Bowman model, the 60 t EAF current on the electrode consumption and The influence of smelting time is shown in Table 1.

Table 1 The influence of current on electrode unit consumption and smelting time

It is generally believed that the two concepts of net consumption and gross consumption coexist in calculating electrode consumption in the smelting process. Net consumption refers to the technical consumption of electrodes consumed by high-temperature sublimation, oxidation, and reaction during smelting; gross consumption is the net consumption and gross consumption. The sum of losses caused by not participating in smelting, that is to say, the graphite electrode consumption model mentioned above is only technical consumption, that is, it is classified as net consumption. Gao Zhanbiao and others believe that the steel industry currently uses the following two methods to calculate graphite electrode consumption.

(1) Production method

The production method is based on the amount of molten steel (finished products) produced in a certain period of time, and the amount of graphite electrode input in the same period minus the remaining amount on the furnace is the consumption.

Gross consumption of graphite electrode per ton of steel

MM=MZ/MG

Net consumption of graphite electrode per ton of steel:

MJ=MC/MG

In the formula: MZ———the total consumption of electrodes (input amount-remaining amount on the furnace), kg/t;

MC———the pure consumption of the electrode (input amount-remaining amount on the furnace-loss amount), kg/t;

MG—The amount of finished molten steel, t.

(2) Power consumption method.

The electricity consumption method is based on the cumulative amount of electricity consumption during the pure heating time in a certain period of time, and the amount of graphite electrode input in the same period is deducted from the remaining amount on the furnace as the consumption (the LF furnace is calculated based on the electricity consumption and the electrode per temperature rise of 1°C) ).

Electrode consumption per kilowatt hour:

MX=1000×MC/QH

In the formula: MC———the pure consumption of electrode (input amount-remaining amount on furnace-loss amount), kg/t;

QH—The cumulative amount of electricity consumption during pure heating time, kW·h.

At this stage, when calculating the electrode loss, iron and steel companies generally include the amount of loss due to not participating in the smelting process at the same time. This can more comprehensively reflect the center of gravity and key points of the loss in the electric arc furnace steelmaking production process, so as to find The deficiencies in the process parameters should be resolved.

- Categories:steel

- Author:

- Origin:

- Time of issue:2020-11-27 10:38

- Views:

The graphite electrode is the last part of the electric arc furnace power supply short network. Through the end of the graphite electrode, a strong electric arc is generated to melt the furnace charge and heat the molten steel. That is, the electrode is the central hub that converts electric energy into heat energy. The electrode is subjected to high temperature when working, and the furnace gas is oxidized. As well as the effects of collapse and impact, especially the connection between the two electrodes, the resistance is larger and the conductivity is lower than other places, and it is easy to trip, oxidize, fall off, and break, which causes great consumption of electrodes and prolongs the smelting time. Reduced productivity.

In 1982, Bowman divided the normal consumption of electrodes into front-end consumption and lateral consumption. Both can be calculated by the following formula:

Electrode normal consumption: CE=Cγ+Cs

Front-end consumption: Cγ=Vγ·TOntap/W, Vγ=Kγ·I2/dnγ

In the formula: TOntap————Electric furnace power supply time, h;

W———Electric furnace tapping weight, t;

Vγ———the front end consumption speed of the electrode, kg/h;

Kγ-front-end consumption constant (Bowman gives Kγ=0.0361 and n usually 0.58 for AC arc furnace);

I-arc current intensity, kA;

dγ—The diameter of the front end of the electrode, m.

Side consumption: Cs=Vs·TTop-Top/W, Vs=3Ks·S

In the formula: TTop-Top --- electric furnace smelting cycle, h;

W———Electric furnace tapping weight, t;

Vs———The consumption speed of the electrode side, kg/h;

Ks———oxidation consumption rate, kg/(m2·h);

S————The oxidation surface area in the electrode furnace, m2.

At present, in the production process, the Bowman electrode consumption model has been widely recognized. Wang Mingli and others believe that once the smelting process is stable, the power supply current has the greatest impact on the electrode unit consumption, and according to the Bowman model, the 60 t EAF current on the electrode consumption and The influence of smelting time is shown in Table 1.

Table 1 The influence of current on electrode unit consumption and smelting time

It is generally believed that the two concepts of net consumption and gross consumption coexist in calculating electrode consumption in the smelting process. Net consumption refers to the technical consumption of electrodes consumed by high-temperature sublimation, oxidation, and reaction during smelting; gross consumption is the net consumption and gross consumption. The sum of losses caused by not participating in smelting, that is to say, the graphite electrode consumption model mentioned above is only technical consumption, that is, it is classified as net consumption. Gao Zhanbiao and others believe that the steel industry currently uses the following two methods to calculate graphite electrode consumption.

(1) Production method

The production method is based on the amount of molten steel (finished products) produced in a certain period of time, and the amount of graphite electrode input in the same period minus the remaining amount on the furnace is the consumption.

Gross consumption of graphite electrode per ton of steel

MM=MZ/MG

Net consumption of graphite electrode per ton of steel:

MJ=MC/MG

In the formula: MZ———the total consumption of electrodes (input amount-remaining amount on the furnace), kg/t;

MC———the pure consumption of the electrode (input amount-remaining amount on the furnace-loss amount), kg/t;

MG—The amount of finished molten steel, t.

(2) Power consumption method.

The electricity consumption method is based on the cumulative amount of electricity consumption during the pure heating time in a certain period of time, and the amount of graphite electrode input in the same period is deducted from the remaining amount on the furnace as the consumption (the LF furnace is calculated based on the electricity consumption and the electrode per temperature rise of 1°C) ).

Electrode consumption per kilowatt hour:

MX=1000×MC/QH

In the formula: MC———the pure consumption of electrode (input amount-remaining amount on furnace-loss amount), kg/t;

QH—The cumulative amount of electricity consumption during pure heating time, kW·h.

At this stage, when calculating the electrode loss, iron and steel companies generally include the amount of loss due to not participating in the smelting process at the same time. This can more comprehensively reflect the center of gravity and key points of the loss in the electric arc furnace steelmaking production process, so as to find The deficiencies in the process parameters should be resolved.

Scan the QR code to read on your phone

Address:

5-503, Beichen Building, Beichen District, Tianjin

Tel:

Email:

Copyright ©2019 Tianjin Fudate Metallurgical Technology Co.,Ltd. 津ICP备20006066号 Powered by www.300.cn